| Jul 26, 2023 |

|

|

|

(Nanowerk Information) Over the past decade, 3D printing applied sciences have skilled unprecedented developments and adjustments. They now allow to manufacture quickly and at a really aggressive price advanced three-dimensional objects. It makes 3D printers particularly enticing and pertinent for numerous fields, together with the aerospace trade or medical units.

|

|

Till just lately, the paradigm in light-based 3D printing or Additive Manufacturing (AM) primarily relied on utilizing a vat of liquid photopolymer resin. An ultraviolet (UV) mild beam cures the resin one layer at a time, while a platform strikes the thing being made downwards after every new layer is hardened.

|

|

The UV mild is both raster scanned to solidify the resin level by level or flashed onto the resin curing the entire layer without delay. Because of the layer-by-layer nature of the printing course of, these light-based AM strategies have main geometric constraints and throughput limitations.

|

|

In a brand new paper printed in Mild: Superior Manufacturing (“Volumetric helical additive manufacturing”), a staff of scientists led by Professor Christophe Moser from Ecole Polytechnique Fédérale de Lausanne have developed a brand new method for bettering the standard of 3D-printed objects with out magnifying the projected patterns.

|

|

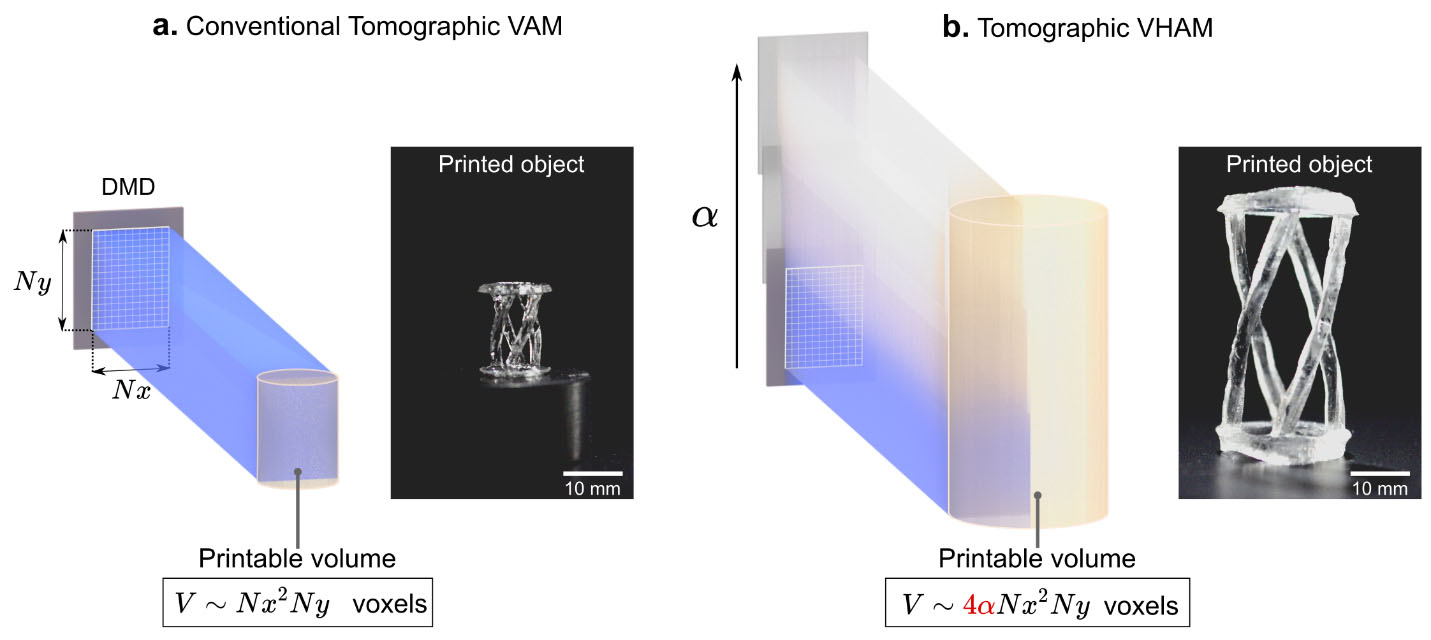

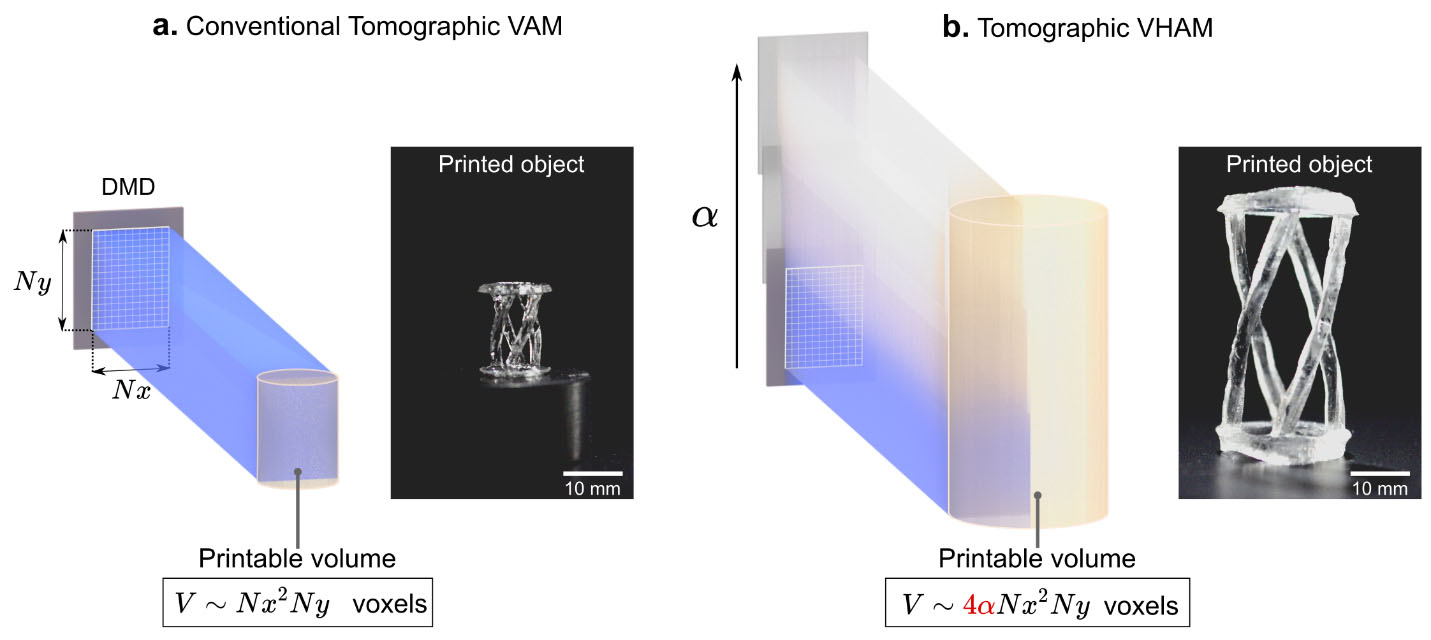

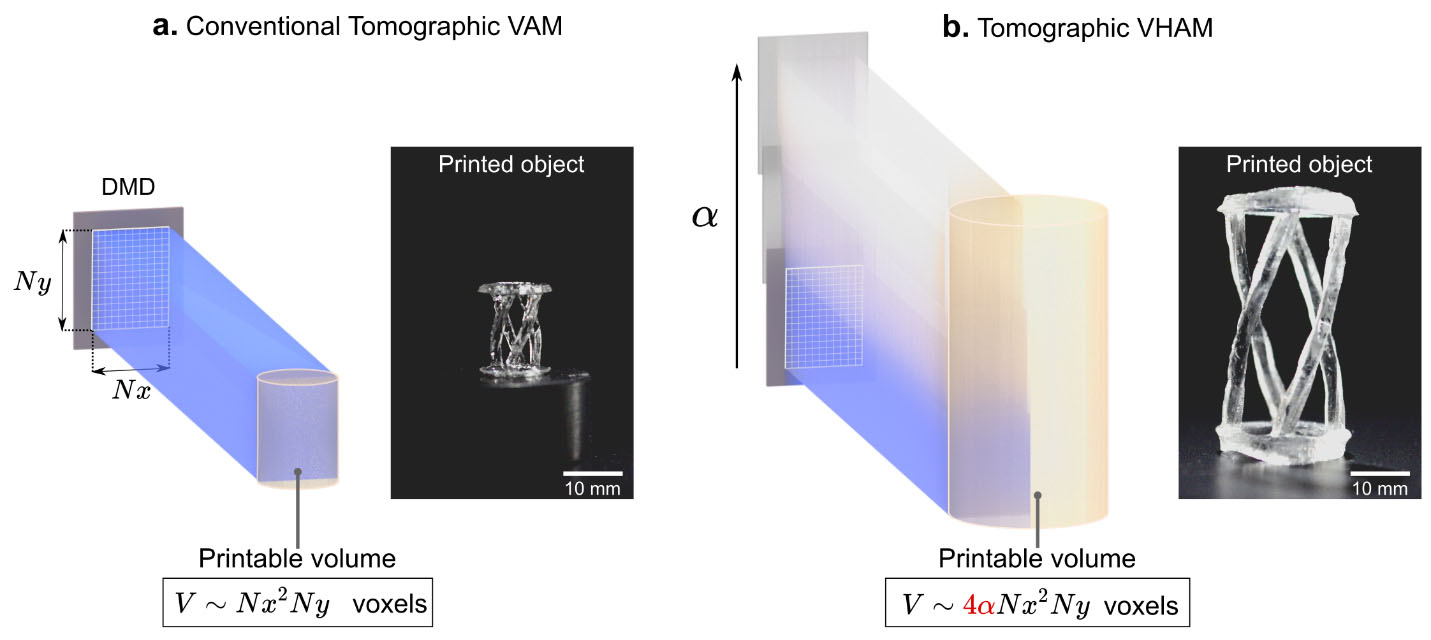

| Rising the variety of printed voxel generated from the identical DMD. a Typical tomographic volumetric additive manufacturing. b Tomographic volumetric helical additive manufacturing. Scale bars: 10 mm.

|

|

The previous few years have seen the emergence of a number of absolutely Volumetric Additive Manufacturing (VAM) applied sciences that transfer away from the layer-by-layer strategy. Two-photon photopolymerization represents the state-of-the-art of volumetric printing with mild. It allows the fabrication of microscale objects with a lateral decision of 100 nm and axial decision of 300 nm. Nevertheless, this course of is sluggish, with a printing pace of simply 1–20 mm3/h and requires costly femtosecond laser sources.

|

|

In the end, the optical decision of the printer dictates the achievable printed voxel dimension. In DLP and tomographic VAM, optical decision is set at finest by the options of the modulator used to sample mild, particularly the DMD.

|

|

The analysis staff used a DLP7000 chip from Texas Devices that has on its floor Nx × Ny = 768 × 1024 micro-mirrors organized in an oblong array able to displaying 8-bit photographs. The DMD picture is magnified by an element 1.66 within the staff’s optical system. The ensuing sample on the vial is 1.74 cm × 2.33 cm with a decision of 23 µm.

|

|

The one solution to enhance the scale of the printed objects with out compromising the decision is to maneuver the DMD for the vial or vice versa. The staff proposed to maneuver the pattern across the mild beam with a helical trajectory. They confirmed that lateral printable dimension might be doubled with out compromising decision by off-centring the optical axis regarding the rotation axis of the photoresin vat.

|

|

Collectively, these two methods enhance the variety of constructing blocks contained in the vial by an element of as much as 12. The out there printed voxels are used to print bigger objects as much as 3 cm × 3 cm × 5 cm in a couple of minutes.

|

|

The analysis staff has mixed a rotating and a linear translation phases to set the glass vial containing the photoresist in a helical movement. The researchers identified that not all of the resin will not be illuminated without delay as in standard tomographic VAM. In VHAM, the entire resin is solely excited solely after one full cycle.

|

|

There are some overlapping areas between the patterns in order that after a flip its decrease and higher components coincide. The scale of the overlap is fine-tuned by adjusting the vial’s rotation pace to the vertical motion of the interpretation stage, which is important to make sure continuity of the printed objects.

|

|

The staff has introduced a proof-of-concept of a brand new light-based method for volumetric printing of multicentimeter scale objects. It builds up on tomographic VAM to considerably enhance the variety of printable voxels whereas retaining the identical mild modulating system for projection and with out compromising an excessive amount of the printing decision. This was achieved by off-centering the sunshine modulator and translating repeatedly the resin vertically alongside the patterned mild beam.

|

|

These easy modifications might be simply made on present tomographic printers and opens up new potentialities for high-resolution and high-speed fabrication of objects whose dimension as much as 3 cm × 3 cm × 6 cm. Helical tomographic VAM is perhaps subsequently interesting for functions in fields the place cm-scale objects should be manufactured individually, akin to within the dental trade, though decision should be improved to fulfill the present necessities of the trade.

|