[ad_1]

(Nanowerk Information) Engaged on the nanoscale provides researchers quite a lot of perception and management when fabricating and characterizing supplies. In bigger scale manufacturing, in addition to in nature, many supplies have the capability for flaws and impurities that may disrupt their complicated construction. This creates a number of weak factors that may simply break beneath stress. That is widespread with most glass, which is why it is regarded as such a fragile materials. Scientists on the Columbia College, College of Connecticut, and the U.S. Division of Vitality’s (DOE) Brookhaven Nationwide Laboratory had been in a position to fabricate a pure type of glass and coat specialised items of DNA with it to create a cloth that was not solely stronger than metal, however extremely light-weight. Supplies that possess each of those qualities are unusual, and additional analysis may result in novel engineering and protection functions. The outcomes had been revealed in Cell Reviews Bodily Science(“Excessive-strength, light-weight nano-architected silica”).

DNA—The Constructing Blocks for Life and Extra

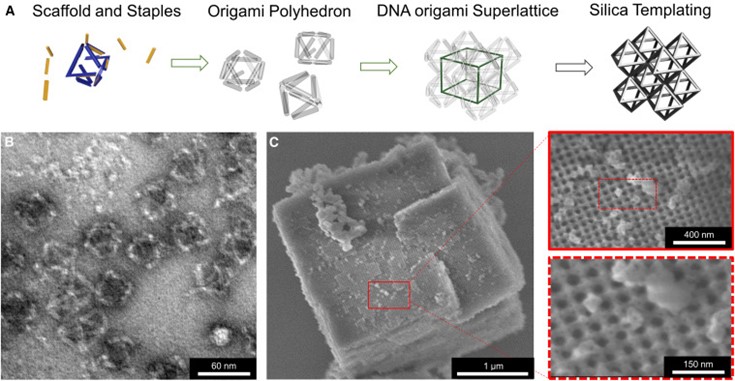

In residing issues, deoxyribonucleic acid, extra generally referred to as DNA, carries organic data that instructs the cells of organisms on learn how to kind, develop, and reproduce. The fabric DNA is product of is named a polymer, a category of powerful, elastic supplies that features plastic and rubber. Their resilience and ease have intrigued materials scientists and impressed many fascinating experiments. Oleg Gang, a supplies scientist on the Heart for Purposeful Nanomaterials (CFN), a DOE Workplace of Science Consumer Facility at Brookhaven Lab, and a professor at Columbia College, has been leveraging DNA’s distinctive properties for supplies synthesis for years, leading to quite a few discoveries. This novel know-how has impressed an array of modern functions—from drug supply to electronics. Gang had beforehand labored with the paper’s lead writer, Brookhaven postdoctoral researcher Aaron Michelson, on an experiment utilizing DNA constructions to construct a sturdy framework for novel supplies. DNA molecules behave in an fascinating approach. The person nucleotides, fundamental items of nucleic acids like DNA and RNA, dictate the bonding between complementary sequences. The exact approach they bond to one another permits scientists to develop strategies to engineer the folding of DNA into particular shapes known as “origami”, named after the Japanese artwork of paper folding. These DNA shapes are nanoscale constructing blocks that may be programmed utilizing addressable DNA bonds to “self-assemble.” Which means well-defined constructions with a repeating sample can spontaneously kind from these origami DNA blocks. A microscopic peek of how these DNA strands kind shapes which might be constructed into bigger lattice constructions which might be coated in silica. CFN, JEOL-1400 TEM and Hitachi-4800 SEM. (Picture: BNL)

These blocks then cling collectively to kind a bigger lattice—a construction with a repeating sample. This course of permits scientists to construct 3D ordered nanomaterials from DNA and combine inorganic nanoparticles and proteins, as demonstrated by the group’s earlier research. After gaining understanding and management of this distinctive meeting course of, Gang, Michelson, and their crew had been then in a position to discover what might be achieved when that biomolecular scaffolding was used create silica frameworks that protect the scaffold structure.

“We targeted on utilizing DNA as a programmable nanomaterial to kind a fancy 3D scaffold,” mentioned Michelson, “and we wished to discover how this scaffold will carry out mechanically when transferred into extra secure solid-state supplies. We explored having this self-assembling materials forged in silica, the primary ingredient in glass, and its potential.”

Michelson’s work on this discipline earned him the Robert Simon Memorial Prize at Columbia College. His analysis into DNA frameworks has explored a spread of traits and functions, from mechanical properties to superconductivity. Very like the constructions he’s constructed upon, Michelson’s work continues to develop and construct because it takes on new layers of data from these thrilling experiments.

The subsequent a part of the fabrication course of was impressed by biomineralization—the way in which sure residing tissue produces minerals to turn into more durable, like bones.

“We had been very to discover how we are able to improve mechanical properties of normal supplies, like glass, however structuring them on the nanoscale,” mentioned Gang.

The scientists used a really skinny layer of silica glass, solely about 5 nm or few hundred atoms thick, to coat the DNA frames, leaving interior areas open and making certain that the ensuing materials is ultra-light. On this small scale, the glass is insensitive to flaws or defects, offering a power that isn’t seen in bigger items of glass the place cracks develop and trigger it to shatter. The crew wished to know precisely how robust this materials was although, which, at this scale, required some very specialised tools.

A microscopic peek of how these DNA strands kind shapes which might be constructed into bigger lattice constructions which might be coated in silica. CFN, JEOL-1400 TEM and Hitachi-4800 SEM. (Picture: BNL)

These blocks then cling collectively to kind a bigger lattice—a construction with a repeating sample. This course of permits scientists to construct 3D ordered nanomaterials from DNA and combine inorganic nanoparticles and proteins, as demonstrated by the group’s earlier research. After gaining understanding and management of this distinctive meeting course of, Gang, Michelson, and their crew had been then in a position to discover what might be achieved when that biomolecular scaffolding was used create silica frameworks that protect the scaffold structure.

“We targeted on utilizing DNA as a programmable nanomaterial to kind a fancy 3D scaffold,” mentioned Michelson, “and we wished to discover how this scaffold will carry out mechanically when transferred into extra secure solid-state supplies. We explored having this self-assembling materials forged in silica, the primary ingredient in glass, and its potential.”

Michelson’s work on this discipline earned him the Robert Simon Memorial Prize at Columbia College. His analysis into DNA frameworks has explored a spread of traits and functions, from mechanical properties to superconductivity. Very like the constructions he’s constructed upon, Michelson’s work continues to develop and construct because it takes on new layers of data from these thrilling experiments.

The subsequent a part of the fabrication course of was impressed by biomineralization—the way in which sure residing tissue produces minerals to turn into more durable, like bones.

“We had been very to discover how we are able to improve mechanical properties of normal supplies, like glass, however structuring them on the nanoscale,” mentioned Gang.

The scientists used a really skinny layer of silica glass, solely about 5 nm or few hundred atoms thick, to coat the DNA frames, leaving interior areas open and making certain that the ensuing materials is ultra-light. On this small scale, the glass is insensitive to flaws or defects, offering a power that isn’t seen in bigger items of glass the place cracks develop and trigger it to shatter. The crew wished to know precisely how robust this materials was although, which, at this scale, required some very specialised tools.

Power Underneath Strain

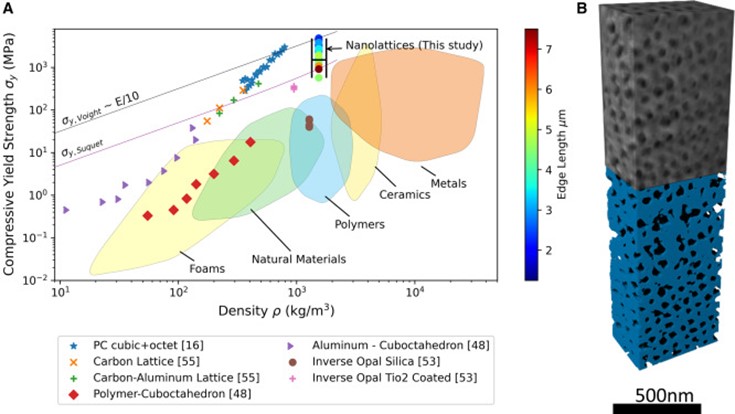

There are easy methods to verify if one thing is sturdy. Poking, pushing, and leaning on surfaces and observing their habits can typically present useful data. Do they bend, creak, buckle, or stand agency beneath the stress? It is a easy, however efficient option to get an understanding of an object’s power, even with out instruments to measure it exactly. How does one press on an object that’s too small to see, although? “To measure the power of those tiny constructions, we employed a way known as nanoindentation,” defined Michelson. “Nanoindentation is a mechanical check on a really small scale carried out utilizing a exact instrument that may apply and measure resistive forces. Our samples are only some microns thick, a couple of thousandth of a millimeter, so it is unattainable to measure these supplies by typical means. Utilizing an electron microscope and nanoindentation collectively, we are able to concurrently measure mechanical habits and observe the method of the compression.” Because the tiny system compresses, or indents, the pattern, researchers can take measurements and observe mechanical properties. They’ll then see what occurs to the fabric because the compression is launched and the pattern returns to its unique state. If there are any cracks that kind or if the construction fails at any level, this precious information might be recorded. When put to the check, the glass-coated DNA lattice was proven to be 4 occasions stronger than metal! What was much more fascinating was that its density was about 5 occasions decrease. Whereas there are supplies which might be robust and thought of pretty light-weight, it has by no means been achieved to this diploma. This system wasn’t one thing that was all the time available at CFN, nevertheless. “We collaborated with Seok-Woo Lee, an affiliate professor on the College of Connecticut, who has experience within the mechanical properties of supplies,” mentioned Gang. “He was a CFN consumer who leveraged a few of our capabilities and assets, like electron microscopes, which is how we developed a relationship with him. We initially didn’t have the aptitude for nanoindentation, however he led us to the correct instruments and received us heading in the right direction. That is one other instance of how scientists from academia and nationwide labs profit from working collectively. We now have these instruments and the experience to take research like this even additional.” A graph evaluating the nanolattice on this experiment to the relative power of varied supplies. (Picture: BNL)

A graph evaluating the nanolattice on this experiment to the relative power of varied supplies. (Picture: BNL)

Constructing One thing New and Thrilling

Whereas there may be nonetheless quite a lot of work to be accomplished earlier than scaling up and desirous about the myriad of functions for such a cloth, there are nonetheless causes for supplies scientists to be enthusiastic about what this implies going ahead. The crew plans to take a look at different supplies, like carbide ceramics, which might be even stronger than glass to see how they work and behave. This might result in even stronger light-weight supplies sooner or later. Whereas his profession continues to be in its early phases, Michelson has already achieved a lot, and is already keen to start out on the subsequent phases of his analysis. “It’s an exquisite alternative to be a postdoc at Brookhaven Lab, particularly after being a Columbia College pupil who would work on the CFN very often,” recalled Michelson. “That is what led me to proceed there as a postdoc. The capabilities that now we have on the CFN, particularly in regard to imaging, actually helped to propel my work.”[ad_2]