[ad_1]

Business has lengthy relied upon energy-intensive processes, akin to distillation and crystallization, to separate molecules that in the end function components in medication, chemical substances and different merchandise.

In current a long time, there was a push to supplant these processes with membranes, that are doubtlessly a lower-cost and eco-friendly various. Sadly, most membranes are produced from polymers that degrade throughout use, making them impractical.

To resolve this downside, a College at Buffalo-led analysis workforce has created a brand new, sturdier membrane that may stand up to harsh environments—excessive temperatures, excessive stress and complicated chemical solvents—related to industrial separation processes.

Made out of an inorganic materials known as carbon-doped steel oxide, it’s described in a research revealed Sept. 7 in Science.

“The processes of separating molecules—whether or not for water desalination, the manufacturing of medication or fertilizers—use an unimaginable quantity of power,” says the research’s corresponding creator, Miao Yu, Ph.D., SUNY Empire Innovation Professor within the Division of Chemical and Organic Engineering within the College at Buffalo Faculty of Engineering and Utilized Sciences.

“What now we have developed is a way to simply fabricate defect-free, sturdy membranes which have inflexible nanopores that may be exactly managed to permit different-sized molecules to go by,” provides Yu, a core college member within the UB RENEW Institute.

The research’s first authors are Bratin Sengupta, a Ph.D. pupil in Yu’s lab, and Qiaobei Dong, Ph.D., who studied below Yu and now works at GTI Power.

Impressed by semiconductors

To create the membrane, the analysis workforce took inspiration from two widespread, however unrelated, manufacturing methods.

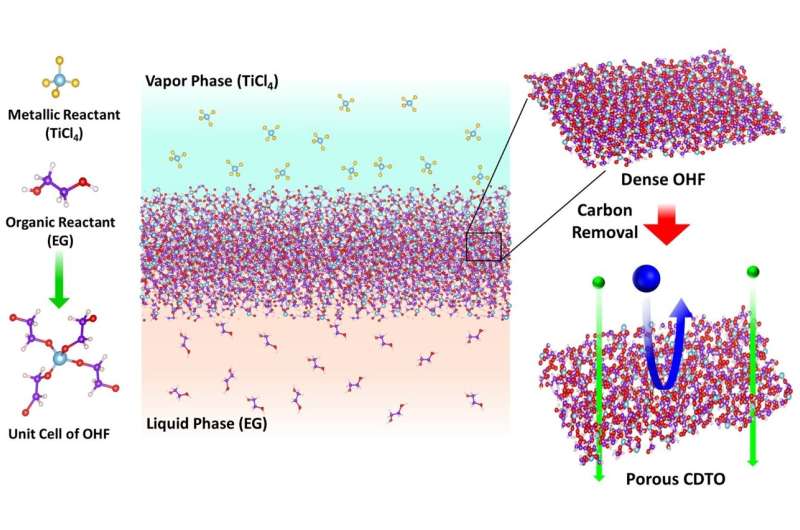

The primary is molecular layer deposition, which entails layering skinny movies of supplies and is most frequently related to semiconductor manufacturing. The second approach is interfacial polymerization, which is a technique of mixing chemical substances that’s generally used to create gasoline cells, chemical sensors and different electronics.

“These strategies will not be new,” says Sengupta, “nonetheless the way wherein we apply them is, and that’s the key to creating our new nanoporous membranes.”

In experiments, researchers merged two low-cost reactants—liquid ethylene glycol and gaseous titanium tetrachloride—on an aluminum-based assist. Inside minutes, the response created a thin-film.

To create the nanopores, they utilized warmth to the movie. The warmth burns off carbon, creating tiny, microscopic holes for molecules to go by. The scale of the nanopores might be anyplace from 0.6 to 1.2 nanometers in diameter—as decided by the calcination gasoline atmosphere, in addition to the quantity and period of warmth.

The strategy permits researchers to keep away from a nagging downside—small holes merging into bigger ones, thus making them extra porous than meant—with creating polymer-based membranes.

Potential to scale back carbon footprint

The brand new membrane can stand up to temperatures as much as 284°F (140°C) and pressures as much as 30 atmospheres when uncovered to natural solvents. These attributes are key as a result of they permit the membrane to separate molecules at excessive temperatures (for many polymer membranes to work, the temperature of the solvents should be lowered, which is dear from an power standpoint).

“From this viewpoint, our membrane has the potential scale back the carbon footprint of many industrial processes,” Yu says.

To reveal the membrane’s effectiveness, the workforce confirmed it may separate boscalid, a fungicide used to guard crops, from its catalyst and beginning reagent. The whole course of occurred at 194°F.

The workforce is planning extra experiments to show the membrane is able to being scaled up for business merchandise. Moreover, Yu plans to start out an organization to additional the expertise’s business viability.

Extra info:

Bratin Sengupta et al, Carbon-doped steel oxide interfacial nanofilms for ultrafast and exact separation of molecules, Science (2023). DOI: 10.1126/science.adh2404

Offered by

College at Buffalo

Quotation:

Separating molecules requires plenty of power. This nanoporous, heat-resistant membrane may change that (2023, September 30)

retrieved 30 September 2023

from https://phys.org/information/2023-09-molecules-requires-lot-energy-nanoporous.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.

[ad_2]